SAN ANGELO, TX — Texas has long been an energy leader in oil and natural gas, but we also now produce more wind-generated electricity than anywhere else in the United States. The wind energy sector that is supplying power to our grid and slashing our electricity bills now faces a growing challenge as it matures: the disposal of wind turbine blades. Innovative Texans, however, are leading the way in solving this problem.

The possibilities for recycling turbines mean they are no longer destined for the landfill. About 85-90% of the materials used in constructing new wind turbines can now be turned into useful byproducts. This significant transformation underscores the industry’s dedication to sustainability, establishing recycling as the new norm.

The primary challenge, the other 10-15% of materials, has involved the turbine blades. With a typical lifespan of about 20 years, these massive blades — each stretching over 170 feet — were once sent to landfills, an expensive and environmentally unfriendly fate. They are made mainly of fiberglass, a resilient composite material traditionally viewed as difficult to reuse.

But recent technological advancements are reshaping this narrative, opening new avenues for recycling these complex components. In Texas, companies like Lubbock-based Pitbull Shredding Solutions are at the forefront of innovation, revolutionizing disposal by shredding old blades to enhance concrete production. This method not only diverts waste from landfills but also contributes to other industries, showcasing a multifaceted approach to sustainability.

Nationally, companies like Veolia North America are also contributing to these efforts. Tennessee-based Carbon Rivers is repurposing fiberglass from old turbine blades for new uses, including manufacturing new turbine components and even products like ballistic armor. The possibilities are endless.

Despite these advancements, critics argue that the industry is too new to handle the impending wave of blade disposals as more turbines reach the end of their lifespan. However, this view overlooks the broader potential here. The challenge of turbine blade disposal should not be seen as a flaw in wind energy but as an opportunity for increased private investment in blade-recycling technologies.

With hundreds of thousands of turbines spinning across Texas, the need for blade disposal solutions is not just inevitable — it represents a lucrative frontier for both start-ups and established firms to innovate and profit. Texas’ wind energy dominance has already created tens of thousands of jobs and injected billions into our economy. Continued support and investment in recycling technologies can transform concerns about turbine blade disposal into a minor footnote in our energy narrative. Overcoming this challenge will clear the path for a more resilient and sustainable energy future in Texas.

As Texans, our tradition of energy innovation continues to grow. Investing in and supporting advanced recycling technologies is not just an environmental or economic necessity but a continuation of our leadership in global energy practices.

This commitment to innovation and sustainability will keep Texas at the forefront of the energy industry, not just in traditional resources but in pioneering the renewable energy landscape. The future of energy is unfolding, and Texas is leading the way.

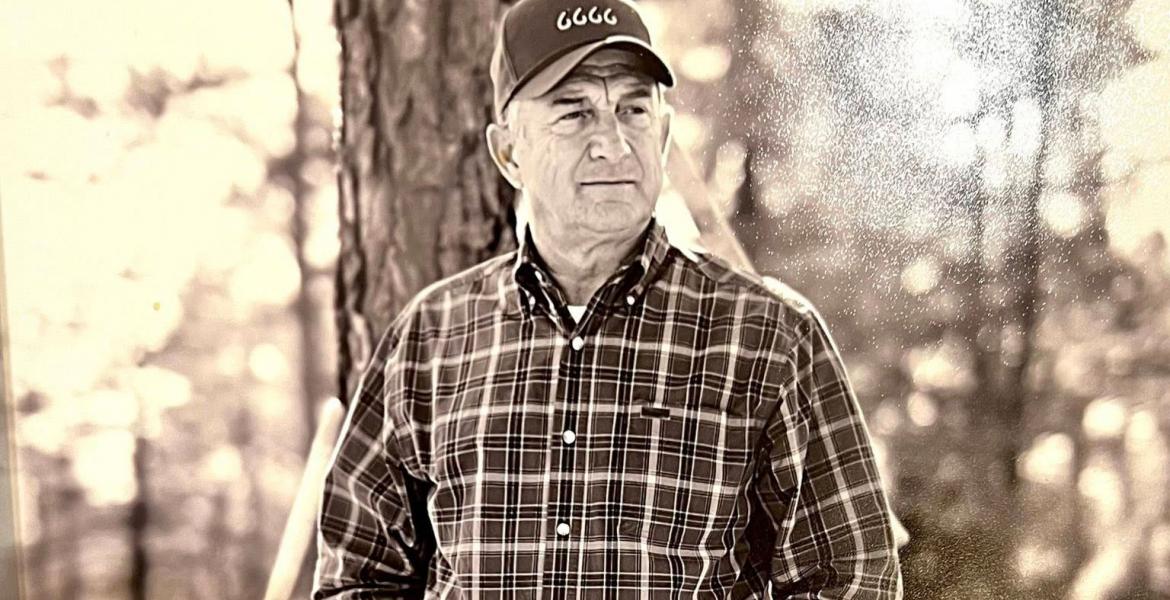

Jaren Tankersley is a Field Representative with the Texas Land & Liberty Coalition, a nonprofit grassroots coalition working with landowners, community leaders, economic development groups, clean energy businesses, and elected officials to promote common-sense policies that advance renewable energy, protect property rights, and benefit local economies.

Subscribe to the LIVE! Daily

Required

Post a comment to this article here: